- Home

- About Us

- product

- Dosing pump

- EMEC

- EMEC chemical Metering Pump

- Solenoid Driven metering pump

- Electromagnetic dosing pump

- Air operated Dosing pump

- Cooling Tower Dosing System

- Chemical transfer pump

- Chlorine Dioxide Generator

- Mixtron Dosing Pump

- EXAT

- Industrial Burner spares

- Swimming pool water filter pump and Accessories

- Swimming Pool Dosing System

- UV Disinfection System

- Air operated Double diaphragm pump

- Fine bubble Diffuser

- Diaphragm Motorized Pump

- Electric Diaphragm Pump

- Enquiry

- Contact Us

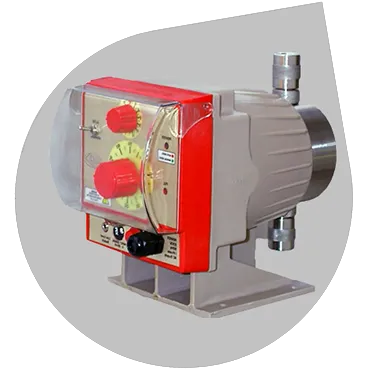

Mechanically Actuated Diaphragm Metering Pump india

Manufacturer of Mechanically Actuated Diaphragm Metering Pump

We Are Leading Manufacturer of Mechanically Actuated Diaphragm Metering Pump in Ahmedabad by Asha Technocrats.Chemicals used in water and waste water treatment typically use mechanically activated diaphragm pumps. It can handle pressures of up to 5 Kg/cm2 and flows at rates between 0 and 720 LPH. This mechanically actuated diaphragm pump is ideally suited for use in low capacity and low pressure applications.The driving unit and the diaphragm are physically connected in a mechanical pump. The diaphragm of a pump that uses hydraulics is moved by pressured hydraulic oil. Both varieties of pumps can be further divided into two groups according on how they regulate volume: either lost motion or amplitude modulation.Peristaltic pumps are widely employed in laboratory and medical applications as metering pumps, but developments in material science have resulted to heavy-duty pumps that can handle very viscous fluids, sludges, and slurries

How Mechanically Actuated Diaphragm Metering Pump Work ?

Diaphragm pumps and peristaltic pumps are both highly helpful and often offer many years of dependable, effective performance.Simple diaphragm pumps have a driving mechanism, a displacement chamber, two valves, and a diaphragm. A flexible membrane called the diaphragm creates suction by vibrating to transport fluid into and out of the pumping chamber. It is situated between the connecting flange and the displacement chamber's side. The two valves are often composed of the same material as the diaphragm and are either flapper valves or spring-loaded ball valves. They work by allowing liquid to enter and exit the chamber. The diaphragm is brought into action by the driving mechanism. Diaphragm pumps use a variety of various drive mechanisms.

Features of Mechanically Actuated Diaphragm pump

- Precise Metering: The mechanical actuation provides precise control over the diaphragm's stroke, ensuring accurate and repeatable flow rates, which is crucial for applications requiring precise dosing.

- Versatility: These pumps can handle a wide range of flow rates and pressures, making them suitable for various industries and applications.

- Reliability: Mechanical actuation tends to be robust and reliable, resulting in consistent pump performance and reduced downtime.

- Leak-Free Operation: The diaphragm acts as a reliable seal, preventing leaks and ensuring safe operation when handling hazardous or costly liquids.

- Chemical Compatibility: Like other diaphragm pumps, mechanically actuated diaphragm metering pumps offer compatibility with a wide range of chemicals

Owned & Powered by : #1 Vinayak InfoSoft - SEO Company Ahmedabad || Disclaimer || Sitemap